Essential Questions:

How do I read a glaze recipe?

Why is it important to test glazes before we use them on our pieces?

Components of Glazes

The Glass Former

Silica is the base material for glass and for ceramic glazes. However, silica melts at about 3100⁰ F (1710⁰ C or cone 32), which is much too hot for ceramic kilns. As such, it cannot be used on its own.

The Refractory

Is used in nearly all glazes as a stiffening agent, allowing glazes to stick to a pot's vertical surface without running off when it has melted.

Fluxes, the Melting Agents

Fluxes lower the melting point of the silica, making it usable to create ceramic glazes.

Various fluxes work in the glaze in their own peculiar way; they are not interchangeable. Some are very active fluxes, allowing glazes to mature at earthenware temperatures. Others are less active, and are useful in mid-range and high-fire temperature.

Colorants and Glaze Modifiers

Silica, when melted, is transparent. Colorants are added to glazes to produce a wide range of hues. Ceramic colorants must be able to withstand high temperature without burning off; most colorants are metallic oxides, which can also affect melt point. This must be taken into account in developing a glaze formula.

In addition to colorants, glazes can also have other modifiers added. These may modify the glazes opacity, iridescence, or working qualities when the glaze is still raw (unfired).

Silica is the base material for glass and for ceramic glazes. However, silica melts at about 3100⁰ F (1710⁰ C or cone 32), which is much too hot for ceramic kilns. As such, it cannot be used on its own.

The Refractory

Is used in nearly all glazes as a stiffening agent, allowing glazes to stick to a pot's vertical surface without running off when it has melted.

Fluxes, the Melting Agents

Fluxes lower the melting point of the silica, making it usable to create ceramic glazes.

Various fluxes work in the glaze in their own peculiar way; they are not interchangeable. Some are very active fluxes, allowing glazes to mature at earthenware temperatures. Others are less active, and are useful in mid-range and high-fire temperature.

Colorants and Glaze Modifiers

Silica, when melted, is transparent. Colorants are added to glazes to produce a wide range of hues. Ceramic colorants must be able to withstand high temperature without burning off; most colorants are metallic oxides, which can also affect melt point. This must be taken into account in developing a glaze formula.

In addition to colorants, glazes can also have other modifiers added. These may modify the glazes opacity, iridescence, or working qualities when the glaze is still raw (unfired).

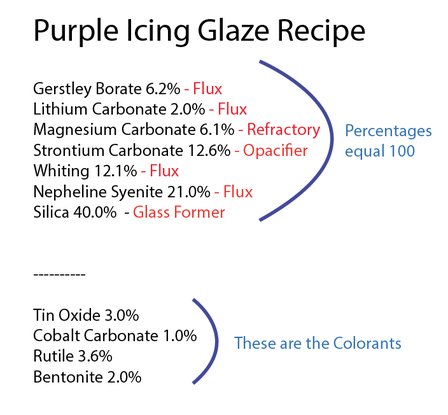

Reading a Glaze Recipe

The basic glaze components will add up to 100. All additions such as colorants and glaze modifiers are given at the end of the recipe as percentages, which are in addition to the basic 100%.

In doing it this way, it makes it much easier to change the colorants and modifiers for a particular base glaze. Or, should you need to, you can more easily change the glaze's basic structure through changing basic ingredients.

In doing it this way, it makes it much easier to change the colorants and modifiers for a particular base glaze. Or, should you need to, you can more easily change the glaze's basic structure through changing basic ingredients.

PROJECT DESCRIPTION

Pair with a classmate and test a CONE 10 glaze recipe that you find online or in a book.

Requirements:

Prep:

Create 5 test tiles- 5 points

Complete Glaze sheet- 5 points

Glazing/Decoration:

Completed Test Tile- 10 points

Reflection:

Self reflection- 5 points

Total points: 25

Requirements:

Prep:

Create 5 test tiles- 5 points

Complete Glaze sheet- 5 points

Glazing/Decoration:

Completed Test Tile- 10 points

Reflection:

Self reflection- 5 points

Total points: 25

TEST TILES

TUTORIAL

Measuring materials, health and safety, mixing with water, etc.